News

News

Company News

您的位置:主页 > News > Company News >

Discussion on the principle and installation direction of the imported triple eccentric butterfly valve mechanism

发布时间:2018-08-03 来源:艾德威尔•瑞拓

Butterfly valve is one of the most rapidly developing valves in recent years. With the development of industrial technology, the application range of butterfly valves is wider and wider, and the variety and quantity are expanding, and they are developing in the direction of high temperature, high pressure, high sealing, large diameter, long life, good adjustment characteristics and multi-function. There are many ways of classifying butterfly valves. Taking the triple eccentric butterfly valve as an example, the installation direction is analyzed in detail.

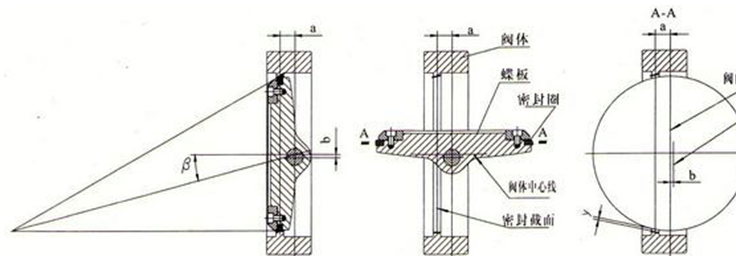

The valve plate rotary center (the center of the valve shaft) forms a A bias in the valve plate seal section and forms a B offset with the valve center; the center line of the valve seal and the seat center line (the body center line) forms a angular offset of the angle of beta.

The installation direction of three eccentric butterfly valve

According to the different arrows on the valve body, the installation direction of the three eccentric butterfly valves can be summarized into 3 situations.

In the first case, the arrow indicating the flow direction of the medium has been marked on the butterfly valve body, which should be installed and used in the direction indicated by the flow direction.

In the second case, there is no indication of any direction on the butterfly valve body. At this time, we should look up the valve manufacturer's instructions, judge the type of butterfly valve, and judge whether there is installation direction according to the structure of the valve, if it is the eccentric butterfly valve, we should pay attention to it.

In the third case, the valve body of the butterfly valve is marked with the arrow of pressure direction (the end of the arrow indicates the compression side). If the builders install the medium as the arrow to the arrow at the time of installation, it will cause the valve seal to become worse and reduce the service life of the valve.

In the actual production process, the triple eccentric butterfly valve side of the valve plate side is the low pressure side, the valve shaft side is the high pressure side, that is the compression side, the pressure of the two sides of the valve is not at the same time, it is good for the valve to close, and conforms to the working requirements of the three eccentric butterfly valve.

Analysis of the reasons for the direction of the butterfly valve installation

The imported three eccentric metal seal butterfly valves usually have its recommended installation direction and do not recommend reverse loading; the domestic eccentric butterfly valve manufacturing technology is relatively poor, usually a leakage rate or one to two pressure grades, and can not be back installed. The reasons are as follows:

A. depends on the structure of the butterfly valve. The middle-line sealing butterfly valve has the same pressure bearing capacity on both sides because of its sealing structure, so the flow direction of the middle-line sealing butterfly valve is not required. Eccentric butterfly valves (including single eccentric, double eccentric and three eccentric butterfly valves) are most required for the flow direction, even if the two-way seal is only positive and negative two directions to meet the sealing requirements under the prescribed pressure level, one side must be able to bear higher pressure and make the tightness better.

B. is easy to repair. Eccentric butterfly valve shaft side is generally high-pressure side, valve plate side is low-pressure side, once installed will lead to the valve leakage during overhaul.

C. is beneficial to the seal of butterfly valve to prevent internal leakage. The sealing between the seat and the sealing surface of the valve plate of the tri-eccentric butterfly valve is realized by pressing the valve plate towards the seat through the torque of the transmission device. When the medium pressure is higher, the tighter the pressure is, the tighter the pressure of the medium pressure is. When the medium pressure increases, the seal begins to leak when the positive pressure between the valve seat and the valve plate is less than the pressure of the medium.

3 concluding remarks

The sealing principle and structure of the eccentric butterfly valve are discussed in this paper in view of the situation that the construction workers often install the eccentric butterfly valve in the wrong direction. After analysis, for eccentric butterfly valves, especially triple eccentric butterfly valve, although each valve manufacturer is called a two-way seal, there is no requirement for the installation direction, but it is only the reverse seal pressure capacity increase, still can not be forward pressure. For triple eccentric butterfly valve, both from the inspection and sealing angle, it shows that it has the direction of installation. The choice of the correct installation direction is not only beneficial to the valve seal, the protection of the valve, the prolongation of the service life of the valve, but also the potential safety hazard to the maximum extent.

Structure schematic diagram of triple eccentric butterfly valve

The valve plate rotary center (the center of the valve shaft) forms a A bias in the valve plate seal section and forms a B offset with the valve center; the center line of the valve seal and the seat center line (the body center line) forms a angular offset of the angle of beta.

The installation direction of three eccentric butterfly valve

According to the different arrows on the valve body, the installation direction of the three eccentric butterfly valves can be summarized into 3 situations.

In the first case, the arrow indicating the flow direction of the medium has been marked on the butterfly valve body, which should be installed and used in the direction indicated by the flow direction.

In the second case, there is no indication of any direction on the butterfly valve body. At this time, we should look up the valve manufacturer's instructions, judge the type of butterfly valve, and judge whether there is installation direction according to the structure of the valve, if it is the eccentric butterfly valve, we should pay attention to it.

In the third case, the valve body of the butterfly valve is marked with the arrow of pressure direction (the end of the arrow indicates the compression side). If the builders install the medium as the arrow to the arrow at the time of installation, it will cause the valve seal to become worse and reduce the service life of the valve.

In the actual production process, the triple eccentric butterfly valve side of the valve plate side is the low pressure side, the valve shaft side is the high pressure side, that is the compression side, the pressure of the two sides of the valve is not at the same time, it is good for the valve to close, and conforms to the working requirements of the three eccentric butterfly valve.

Analysis of the reasons for the direction of the butterfly valve installation

The imported three eccentric metal seal butterfly valves usually have its recommended installation direction and do not recommend reverse loading; the domestic eccentric butterfly valve manufacturing technology is relatively poor, usually a leakage rate or one to two pressure grades, and can not be back installed. The reasons are as follows:

A. depends on the structure of the butterfly valve. The middle-line sealing butterfly valve has the same pressure bearing capacity on both sides because of its sealing structure, so the flow direction of the middle-line sealing butterfly valve is not required. Eccentric butterfly valves (including single eccentric, double eccentric and three eccentric butterfly valves) are most required for the flow direction, even if the two-way seal is only positive and negative two directions to meet the sealing requirements under the prescribed pressure level, one side must be able to bear higher pressure and make the tightness better.

B. is easy to repair. Eccentric butterfly valve shaft side is generally high-pressure side, valve plate side is low-pressure side, once installed will lead to the valve leakage during overhaul.

C. is beneficial to the seal of butterfly valve to prevent internal leakage. The sealing between the seat and the sealing surface of the valve plate of the tri-eccentric butterfly valve is realized by pressing the valve plate towards the seat through the torque of the transmission device. When the medium pressure is higher, the tighter the pressure is, the tighter the pressure of the medium pressure is. When the medium pressure increases, the seal begins to leak when the positive pressure between the valve seat and the valve plate is less than the pressure of the medium.

3 concluding remarks

The sealing principle and structure of the eccentric butterfly valve are discussed in this paper in view of the situation that the construction workers often install the eccentric butterfly valve in the wrong direction. After analysis, for eccentric butterfly valves, especially triple eccentric butterfly valve, although each valve manufacturer is called a two-way seal, there is no requirement for the installation direction, but it is only the reverse seal pressure capacity increase, still can not be forward pressure. For triple eccentric butterfly valve, both from the inspection and sealing angle, it shows that it has the direction of installation. The choice of the correct installation direction is not only beneficial to the valve seal, the protection of the valve, the prolongation of the service life of the valve, but also the potential safety hazard to the maximum extent.