News

News

您的位置:主页 > News > Company News >

Triple eccentric butterfly valve, what is the triple eccentric butterfly valve

Triple eccentric butterfly valve has a history of more than 50 years from the invention to now. In these 50 years, people have also been improving the three eccentric butterfly valves, which makes the application field of triple eccentric butterfly valve more extensive. The original triple eccentric butterfly valve are only used for the intercept and connection of water medium, and the three eccentric design strengthens the function of the butterfly valve. It has become one of the valves with excellent performance under the worst conditions of the key process environment.

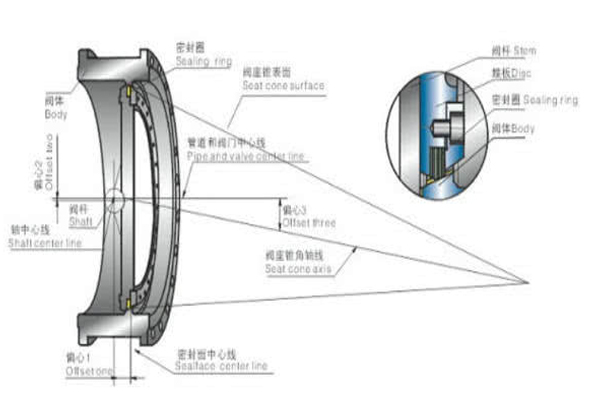

1) the center line of the sealing surface of the disc / seat.

2) the position of the axis of the axis relative to the hole;

3) the axis of the valve seat cone angle deviating from the center line of the valve hole.

Three eccentric butterfly valve, what is the three eccentric butterfly valve

The three offset combinations provide a conical seal face to minimize the wear between the three eccentric butterfly valve seats and the seals, and improve the life and sealing of the three eccentric butterfly valve. In addition, reduce the valve seat surface to the minimum and reduce the working torque of the three eccentric butterfly valve.

Generally speaking, the three eccentric butterfly valve has better sealing performance and cost than other metal seated valve types. Because of its compact structure, the slewing design and lightweight structure are easy to install and operate, and they do not require tube support. Replaceable seal rings, allowing quick and simple maintenance and low torque (allowing smaller drives) mean more cost savings.

Two way zero leakage closed metal seat has only one soft seat valve. This will greatly expand the possibility of application. Flexible seal rings and optimal torque transmission, which means that these valves can provide fire safety design and sealing performance, which can be larger than the maximum temperature range of the general butterfly valve. Traditionally, oil and gas processing, oil refining, chemical and petrochemical plants, power generation, offshore platforms, heating, paper, steel Mills, sugar Mills, seawater desalination, water treatment and distribution may be found in a large number of industries. Their use in all industries has increased stringent government regulations and increased production demand, forcing users to seek solutions. Dosage is also rising, and has been around for decades, and features offer many good solutions, including those with greater challenges. These benefits include operational efficiency, wear resistant media and chemicals to a certain temperature or pressure, and versatility in a wide range of operating conditions.

Three eccentric butterfly valve, what is the triple eccentric butterfly valve.

Using the features of the design, the functions provided by the next generation design can further improve the safety and performance of the tri-eccentric butterfly valve, including:

1, the use of precision machined sealing surface and sealing ring to form metal to metal seal. Even in high temperature and high pressure and other harsh service environment, two-way seal and zero leakage can be achieved. The standard right angle conical design of low friction and streamline shape, metal can solve heat expansion and contraction of metal well, and it is an important feature of high temperature and high pressure environment service. Metal to metal seals are allowed to be used in oil fields with fire protection requirements.

2. The best seat cover design. The seat sealing surface is used to weld the Stellite hard alloy on the valve body. The seal face has longer life and better wear resistance, even if repeated cycle is used. The design of the sealing structure reduces friction with the butterfly plate and reduces the working torque.

3. Special valve seat design uses valve to automatically adjust valve seal. The floating seal ring and a wide sealing ring support gasket are more reliable by using sealing and opening and closing. This seat ensures that the valve has a two-way sealing feature.

4. The positioning pin of the valve design is located at a very low position on the butterfly plate, allowing good performance during thermal expansion, minimizing the disturbance of the stem to the greatest extent. Therefore, the valve has a long service life.