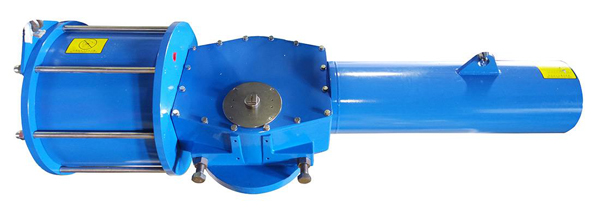

Scotch yoke pneumatic actuator is a kind of pneumatic actuator. Besides the pneumatic fork actuator, there are film type, piston type and gear rack type. Each actuator is suitable for different places because of its different working principles.

The actuating mechanism and regulating mechanism of pneumatic actuator are unified as a whole. The actuating mechanism of pneumatic actuator includes film type, piston type, fork type and gear rack type. The piston stroke is long and suitable for situations requiring greater thrust, while the membrane stroke is small and can only drive the valve stem directly. Pneumatic fork actuator has the characteristics of large torque, small space, and the torque curve is more in line with the torque curve of the valve. It is often used on the valve with large torque. The rack-and-pinion pneumatic actuator has the advantages of simple structure, stable and reliable operation, and safety and explosion-proof. It is widely used in power plants, chemical industry, oil refining and other production processes with high safety requirements.

When compressed air enters the pneumatic actuator from nozzle A, the gas pushes the two pistons to move in a straight line toward both ends (cylinder head end). The rack on the piston drives the gear on the rotating shaft to rotate 90 degrees counterclockwise, and the valve is opened. At this time, the gas at both ends of the pneumatic actuating valve is discharged with the B-tube nozzle. Conversely, when the compressed air enters the two ends of the pneumatic actuator from the B-shaped nozzle, the gas pushes the double plugs to move in a straight line towards the middle. The rack on the piston drives the gear on the rotating shaft to rotate 90 degrees clockwise, and the classic valve is closed. At this time, the gas in the middle of the pneumatic actuator is discharged with the A-tube nozzle. The above is the standard transmission principle. According to user's demand, pneumatic actuator can be equipped with the transmission principle opposite to the standard type, that is, to select the standard axis to turn clockwise to open the valve and counter-clockwise to turn to close the valve. Single-acting (spring reset) pneumatic actuator A pipe nozzle is the intake port, B pipe nozzle is the exhaust port (B pipe nozzle should be installed muffler). The inlet of A-tube nozzle is to open the valve, and the valve is closed by spring force when the air is cut off.

Above are the characteristics and working principles of several kinds of

scotch yoke pneumatic actuator, which can be used for your reference when choosing and purchasing.