News

News

您的位置:主页 > News > Industry News >

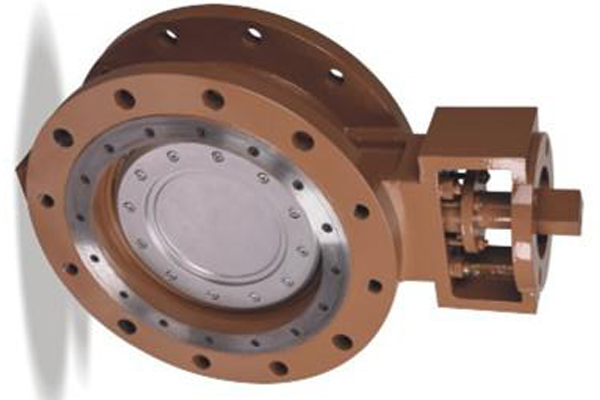

Processing of triple eccentric butterfly valve

Compared with other valves triple eccentric butterfly valve has the advantages of short structure length, light weight, good sealing, small operating torque, quick opening and closing, and long service life. However, the seal face of the butterfly plate of three eccentric metal hard seal butterfly valve is inclined conical surface, which can only realize only one way pressure seal, that is, the higher the pressure is, the better the seal is, but the reverse pressure seal performance is poor, generally not more than 0.5MPa, which restricts the application of three eccentric metal hard seal butterfly valves. Through analysis, the processing technology of parts and components and the matching tolerance are improved, so that the three-eccentric metal hard-sealed butterfly valve achieves two-way zero leakage. The concrete methods are as follows:

Triple eccentric butterfly valve disc stem hole and valve stem hole processing generally in boring machine finishing boring. In order to reduce the coaxiality error, the percentage meter is placed on the spindle after the installation of the tooling and valve body is put in place. The axis is rotated to correct the valve body channel along the center line of the spindle, boring one end hole, and then adding a dial to correct the other end after 180 degree rotation of the assembly table.

2, plate processing

Triple eccentric butterfly valve sealing surface generally adopts a combined type sealing ring. The structure has "metal + graphite" and "metal + PE". When the sealing surface is processed, the disc, sealing component and pressing ring are assembled together, and the sealing surface is processed to the size on the inclined die. If the "metal + graphite" sealing component is processed, graphite is replaced by metal process sealing ring. If the "metal + PTEE" is processed, PTEE is easy to deform and affect the seal, so in the processing, 0.8 to 1mm machining allowance is reserved for the plate, sealing component and ring component sealing surface with reference to the drawing size, so that even when the PTEE is assembled, there is room for adjustment.

3. The selection of the tolerance of seal

When the sealing component is the structure of "metal +PTFE", the seal is not leaked at pressure test during pressure testing, and the greater the pressure is, the more obvious the phenomenon is. Once the screws of the sealing components are released, the pressure is re pressed, and the above problems occur again. The reason is that with the increase of sealing pressure in the test pressure, the force of the sealing component is shrinking, and the PTFE seal ring can not recover the original shape and leak when the screw is tightened. Due to the limitation of the butterfly valve structure, it is not possible to increase the screw force by increasing the length and number of screws.

From the design point of view, the fit tolerance of the sealing component and the butterfly plate is DLL / Dll. We can change the tolerance of the inner diameter of the PTFE seal ring to Js9, and the positioning step tolerance of the butterfly plate is changed to H9, and the tolerance of the inner diameter of the metal seal ring is still D11 for the easy assembly. When the tolerance is changed, the clearance between the PTFE seal ring and the butterfly plate is smaller, and the internal contraction is restrained. At the same time, when the valve detects the process to release pressure, the leakage problem of the valve seal is also solved.