News

News

Company News

您的位置:主页 > News > Company News >

Triple eccentric butterfly valve sealing surface processing method

发布时间:2018-07-16 来源:艾德威尔•瑞拓

1 overview

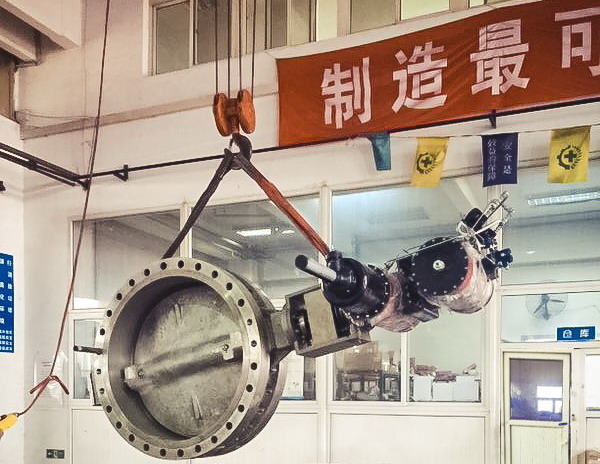

Triple eccentric butterfly valve sealing surface is inclined cone, the body sealing ring in contact with the sealing ring of the butterfly plate assembly for surface contact, its working principle is to rely on drive torque direct drive disc assembly, the butterfly plate assembly produce elastic deformation after sealing and good contact with the body sealing ring and sealing. As a kind of high performance valve, three-eccentric metal hard sealing butterfly valve has the advantages of good corrosion resistance, reliable sealing and small opening torque. Three partial hardness electric butterfly valve sealing 48 "), in which the body sealing ring material is 1 cr18ni9ti, butterfly plate assembly seal material for composite stainless steel plate and asbestos powder layer assembly, body sealing ring and sealing ring of the butterfly plate assembly processing quality directly decides the butterfly valve sealing performance.

2 processing technology

From structural characteristics analysis of triple eccentric butterfly valve, butterfly plate assembly seal for stainless steel plate and asbestos board assembly, body sealing ring for hard alloy, high hardness, feed quantity is difficult to control, not easy forming in one time, and high requirement of machining surface roughness. In order to ensure the processing requirements, the technological process for the valve or butterfly plate assembly - the body sealing ring rough machining carbide surfacing, 12 h heat preservation, heat treatment to eliminate the thermal stress, tooling precision tooling coarse car seal face - on car seal face, grinding head grinding on the seal face, valve body and disc assembly or boring shaft hole, strength test, seal test.

3 processing tooling

The valve body of triple eccentric butterfly valve shall be sealed as a seal ring and welded into the valve body. In 2.5 m cars will compound good body clamping on the body sealing ring processing equipment, the vertical lathe tool rod rotation 8 °, according to the drawings design requirements, after alignment along the tapered generatrix direction knife, the size of the car to before welding of stainless steel. Then surfacing the stainless steel, after zui, the welded stainless steel valve body will be re-mounted on the stand car, according to the above method of the valve body sealing ring to the required size in the drawing. Finally, the grinding head is mounted on the tool holder of the standing car and the sealing ring of the valve body is grinded to meet the roughness requirement of the drawing design.

5. Sealing ring processing of panel assembly

Triple eccentric butterfly valve sealing butterfly plate assembly of parts is sealing ring, sealing ring for the oblique cone structure, the cone apex Angle of 16 °, thickness of 13.5 mm, from 5 asbestos board and 4 layer compounded of stainless steel plate. The sealing ring must be assembled together with butterfly plate and pressure ring, so as to prevent the stainless steel plate and asbestos plate from warping in the sealing ring interlayer. According to its structure characteristics, the butterfly plate assembly seal adopts the following processing method: (1) in 2.5 m respectively set up the car before the butterfly plate and the seam allowance on the pressure ring size processing to the drawings requirements, cylindrical not processing; (2) drilling the pressure ring and tapping the regulating plate according to the drawing requirements; (3) the pressure ring, sealing ring and butterfly plate shall be assembled according to the drawing, and the butterfly plate assembly shall be bolted to the valve body assembly, and then the butterfly plate assembly shall be clamped on it. Vertical lathe tool rod rotating 8 ° pressure ring, sealing ring and disc to grinding size; The same thickness steel plate is used to replace the sealing ring, the pressure ring and the adjustment plate cone surface to the drawing size. (5) tooling, will pressure ring, sealing ring, disc assembly according to the requirement again, and then in a vertical lathe tool post grinding head, grinding was carried out on the sealing ring processing, roughness to the drawings design requirements.

6 valve stem shaft hole processing

Butterfly plate assembly into the valve body, adjust the relative position of the butterfly plate assembly and valve body, after the saponification liquid, no leakage, for 5 minutes to compact disc assembly, or boring shaft hole of the valve body and disc.

Adopting this method processing the body sealing ring and sealing ring, disc assembly is convenient for operation, high working efficiency, and ensure the accuracy of the seal face geometry well, the strength test and seal test have reached the design requirements, has a good practical value and popularization value.

Triple eccentric butterfly valve sealing surface is inclined cone, the body sealing ring in contact with the sealing ring of the butterfly plate assembly for surface contact, its working principle is to rely on drive torque direct drive disc assembly, the butterfly plate assembly produce elastic deformation after sealing and good contact with the body sealing ring and sealing. As a kind of high performance valve, three-eccentric metal hard sealing butterfly valve has the advantages of good corrosion resistance, reliable sealing and small opening torque. Three partial hardness electric butterfly valve sealing 48 "), in which the body sealing ring material is 1 cr18ni9ti, butterfly plate assembly seal material for composite stainless steel plate and asbestos powder layer assembly, body sealing ring and sealing ring of the butterfly plate assembly processing quality directly decides the butterfly valve sealing performance.

2 processing technology

From structural characteristics analysis of triple eccentric butterfly valve, butterfly plate assembly seal for stainless steel plate and asbestos board assembly, body sealing ring for hard alloy, high hardness, feed quantity is difficult to control, not easy forming in one time, and high requirement of machining surface roughness. In order to ensure the processing requirements, the technological process for the valve or butterfly plate assembly - the body sealing ring rough machining carbide surfacing, 12 h heat preservation, heat treatment to eliminate the thermal stress, tooling precision tooling coarse car seal face - on car seal face, grinding head grinding on the seal face, valve body and disc assembly or boring shaft hole, strength test, seal test.

3 processing tooling

Triple eccentric butterfly valve plate assembly seal ring and valve body seal ring seal cover (processing surface) are inclined cone. The body sealing ring of the vertical Angle of the center line of the cone and space is 8 °, butterfly plate assembly seal cone of the vertical centerline and space Angle 8 °.

The valve body of triple eccentric butterfly valve shall be sealed as a seal ring and welded into the valve body. In 2.5 m cars will compound good body clamping on the body sealing ring processing equipment, the vertical lathe tool rod rotation 8 °, according to the drawings design requirements, after alignment along the tapered generatrix direction knife, the size of the car to before welding of stainless steel. Then surfacing the stainless steel, after zui, the welded stainless steel valve body will be re-mounted on the stand car, according to the above method of the valve body sealing ring to the required size in the drawing. Finally, the grinding head is mounted on the tool holder of the standing car and the sealing ring of the valve body is grinded to meet the roughness requirement of the drawing design.

5. Sealing ring processing of panel assembly

Triple eccentric butterfly valve sealing butterfly plate assembly of parts is sealing ring, sealing ring for the oblique cone structure, the cone apex Angle of 16 °, thickness of 13.5 mm, from 5 asbestos board and 4 layer compounded of stainless steel plate. The sealing ring must be assembled together with butterfly plate and pressure ring, so as to prevent the stainless steel plate and asbestos plate from warping in the sealing ring interlayer. According to its structure characteristics, the butterfly plate assembly seal adopts the following processing method: (1) in 2.5 m respectively set up the car before the butterfly plate and the seam allowance on the pressure ring size processing to the drawings requirements, cylindrical not processing; (2) drilling the pressure ring and tapping the regulating plate according to the drawing requirements; (3) the pressure ring, sealing ring and butterfly plate shall be assembled according to the drawing, and the butterfly plate assembly shall be bolted to the valve body assembly, and then the butterfly plate assembly shall be clamped on it. Vertical lathe tool rod rotating 8 ° pressure ring, sealing ring and disc to grinding size; The same thickness steel plate is used to replace the sealing ring, the pressure ring and the adjustment plate cone surface to the drawing size. (5) tooling, will pressure ring, sealing ring, disc assembly according to the requirement again, and then in a vertical lathe tool post grinding head, grinding was carried out on the sealing ring processing, roughness to the drawings design requirements.

6 valve stem shaft hole processing

Butterfly plate assembly into the valve body, adjust the relative position of the butterfly plate assembly and valve body, after the saponification liquid, no leakage, for 5 minutes to compact disc assembly, or boring shaft hole of the valve body and disc.

Adopting this method processing the body sealing ring and sealing ring, disc assembly is convenient for operation, high working efficiency, and ensure the accuracy of the seal face geometry well, the strength test and seal test have reached the design requirements, has a good practical value and popularization value.