News

News

Company News

您的位置:主页 > News > Company News >

The possible failure and method of high temperature butterfly valve

发布时间:2018-06-15 来源:艾德威尔•瑞拓

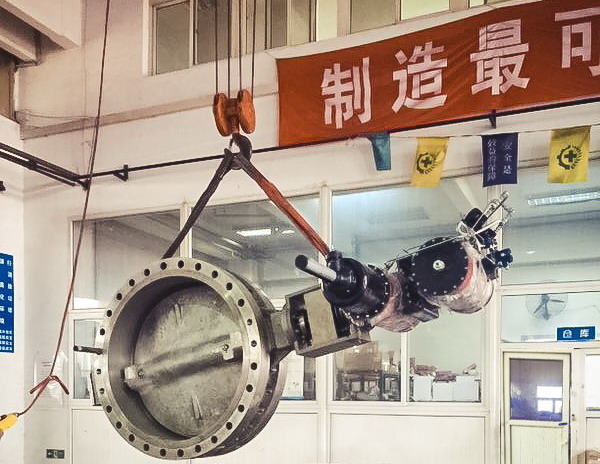

With the high temperature butterfly valve has been applied to various industries with its own advantages, and with the wide use of high temperature butterfly valve, few people know how to solve the problem in the use of the butterfly valve, and we will analyze the possible failure and cleaning method of the high temperature butterfly valve.

1.seal leakage

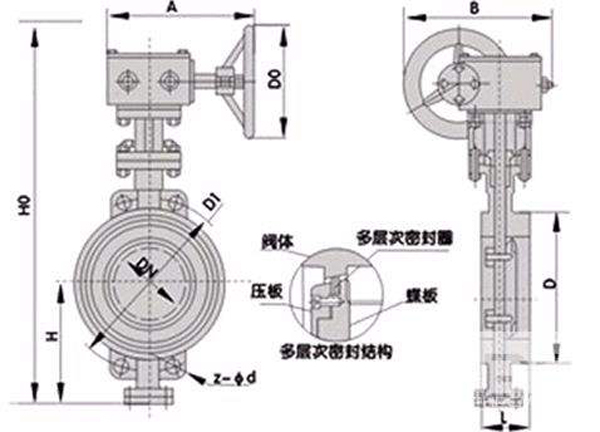

(1) the butterfly plate and the seal ring have sundries. Remove impurities and clean the inner cavity of the valve.

(2) the closing position of the butterfly plate and the sealing ring is not consistent. Adjust the adjusting screw of actuator such as turbine or electric actuator to achieve the correct valve closing position.

(3) flange bolts are not uniformly or unevenly loaded at the exit. Check the loading flange plane and bolt tightening force, and press evenly.

(4) the direction of test pressure is not required. Press the arrow in the direction of the seal.

2. Leakage at both ends of the valve

(1) the sealing gaskets on both sides failed. Replace the sealing gasket;

(2) the pressure of the pipe flange is not pressed. Compress the flange bolt (uniform force);

(3) on the seal ring, the lower seal gasket is invalid. Unload the pressure plate ring of the valve and replace the sealing ring failure gasket.

3. Leakage at the filler

(1) fillers are out of date and aging. 1., aging should be replaced in time. The damaged fillers will be placed by lap, and the joints will be 30-45 degrees.

(2) when the operation is too strong, 2. should be subjected to normal force and uniform operation.

(1) incorrect use. No pipe clamp, long lever, impact tool, etc. are prohibited.

(2) the fasteners are loose and ready to be repaired at any time.

(3) handle, hand wheel and stem connection damage. Repair at any time.

5, turbine, vortex bar drive card bite

(1) the uncleanliness is embedded in the dirt and affects the lubrication. Remove the stolen goods, keep clean, and go on regular refueling.

(2) poor operation. If the card is found to bite when the operation is carried out and the resistance is too great, it can not continue to operate.

6. Fault of electric installation

(1) poor lubrication, the valve has foreign matter stuck, causing excessive torque damage. On the fuel, make the tubing good, the seasoning should be properly pressed, and timely remove the foreign body in the valve and keep it clean.

(2) motor failure. Motor working time not exceeding 15 minutes, power supply should be normal, avoid motor damp.

1.seal leakage

(1) the butterfly plate and the seal ring have sundries. Remove impurities and clean the inner cavity of the valve.

(2) the closing position of the butterfly plate and the sealing ring is not consistent. Adjust the adjusting screw of actuator such as turbine or electric actuator to achieve the correct valve closing position.

(3) flange bolts are not uniformly or unevenly loaded at the exit. Check the loading flange plane and bolt tightening force, and press evenly.

(4) the direction of test pressure is not required. Press the arrow in the direction of the seal.

2. Leakage at both ends of the valve

(1) the sealing gaskets on both sides failed. Replace the sealing gasket;

(2) the pressure of the pipe flange is not pressed. Compress the flange bolt (uniform force);

(3) on the seal ring, the lower seal gasket is invalid. Unload the pressure plate ring of the valve and replace the sealing ring failure gasket.

3. Leakage at the filler

(1) fillers are out of date and aging. 1., aging should be replaced in time. The damaged fillers will be placed by lap, and the joints will be 30-45 degrees.

(2) when the operation is too strong, 2. should be subjected to normal force and uniform operation.

(3) the packing sleeve bolts are not tightened. 3., tighten evenly and press the bolts for packing.

(1) incorrect use. No pipe clamp, long lever, impact tool, etc. are prohibited.

(2) the fasteners are loose and ready to be repaired at any time.

(3) handle, hand wheel and stem connection damage. Repair at any time.

5, turbine, vortex bar drive card bite

(1) the uncleanliness is embedded in the dirt and affects the lubrication. Remove the stolen goods, keep clean, and go on regular refueling.

(2) poor operation. If the card is found to bite when the operation is carried out and the resistance is too great, it can not continue to operate.

6. Fault of electric installation

(1) poor lubrication, the valve has foreign matter stuck, causing excessive torque damage. On the fuel, make the tubing good, the seasoning should be properly pressed, and timely remove the foreign body in the valve and keep it clean.

(2) motor failure. Motor working time not exceeding 15 minutes, power supply should be normal, avoid motor damp.